Flexarmor rubber products are custom designed and manufactured to withstand the harsh conditions of the primary mining and aggregate industry.

They are designed to help optimize the performance of your production operations and reduce your operating costs per ton.

Each product is developed in collaboration with you, according to the technical information and parameters you provide us, in order to solve the specific problems of wear, impact, and noise level of your applications.

We combine our expertise in rubber molding with our ability to combine rubber with other materials such as ceramics, steel, carbide overlays and high chrome white iron to provide a solution that is totally tailored to your needs.

The final Flexarmor product is thereby tailored made for you in shape, thickness, material and mounting system, then supplied in a ready-to-install package.

For all Flexarmor products, the preparation of rubber compounds, product design and vulcanization molding are done locally, through short manufacturing channels in order to provide you short lead times.

We are proud to support the mining and aggregate industry with innovative, custom-designed rubber products made in Canada.

Due to its unique physical properties, rubber offers high energy absorption, excellent abrasion resistance and reduction of audible noise in impact situations.

This makes it an excellent material to prevent structural damages due to impact, maximize wear life on sliding or rubbing applications and greatly reduce ambient noise levels near loading applications.

Flexarmor products are manufactured from proprietary rubber compounds developed to maximize cut and abrasion resistance properties.

Flexarmor products are made from unique proprietary rubber compounds developed by Soluroc to address specific industry issues.

Some compounds are developed with the objective of resisting wear and cuts due to impact, while other compounds have lubricating, anti-stick, dielectric or combustion resistance properties.

Each compound is therefore tailored to specific industry issues, making the final Flexarmor rubber product a custom-made solution for the needs of each application.

All rubbers are not born equal!

To optimize the performance of a Flexarmor rubber solution, we can combine it with various other materials with specific impact and abrasion resistance properties.

Based on the technical information you provide us on the wear profiles of your application, we analyze impact angles, height of drop, rock density and size of rock fragmentation in order to properly evaluate the need for add-on material on certain surfaces.

Add-on materials can be fabric layers, Steelguard carbide steel plates, Abreco high chrome white iron blocks, HT steel plates or ceramic pellets.

Each of these materials offers specific impact and abrasion performance, which helps us provide a solution tailored to your needs.

Flexarmor products are fitted to equipment structures by mechanical bolting or with magnets.

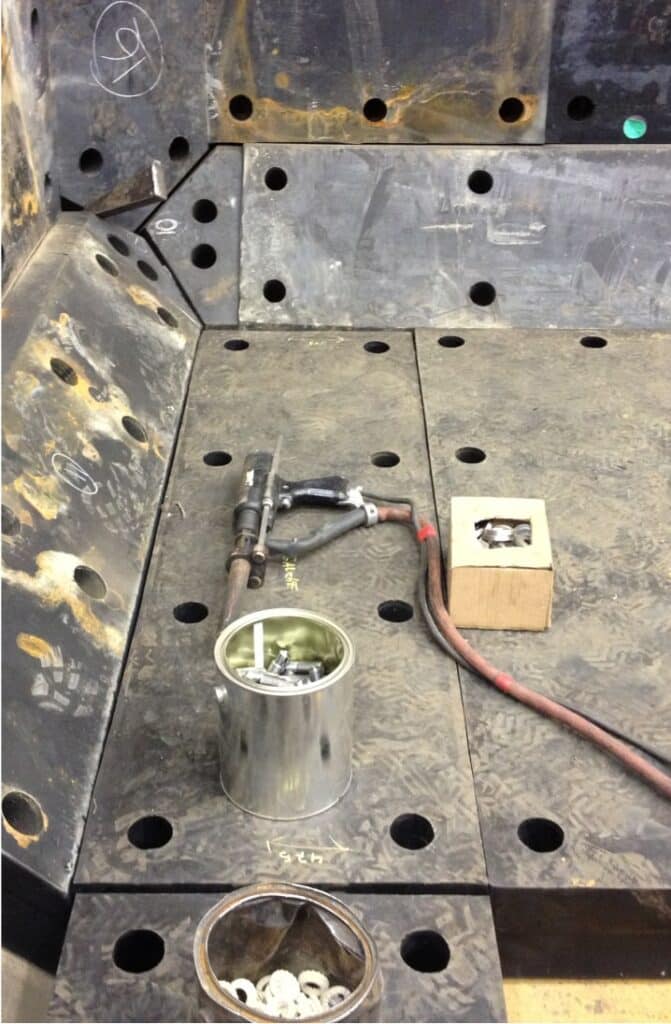

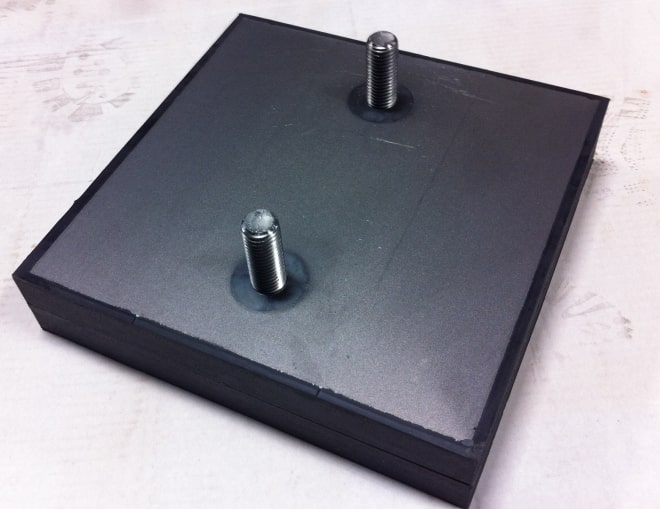

Bolting can be done in a variety of ways through the structure or on one side of the structure using Nelson type welded threaded studs.

For some applications, where freedom of movement is desired, it is also possible to use chains to suspend a Flexarmor solution.

See the different assembly types:

The Flexarmor product line offers a multitude of solutions for applications in the mining and aggregate industry. Since mining and aggregate applications are exposed to high impact and abrasion, rubber is an ideal material to solve these problems.

Designed for mining trucks, Flexarmor products are optimized to meet the needs of the industry in order to improve truck body life, reduce structural damage, increase truck body availability and minimize operating costs per ton.

Optimize the installation and replacement time of your wear liners by using Flexarmor’s magnetic rubber liners.