Steelguard’s line of Carbide Overlay (CCO) wear products are designed to withstand the most demanding applications.

Used to eliminate wear problems in a variety of industries, Steelguard solutions are custom-made to optimize your operations.

Each product concept is developed based on the technical information you provide us, in order to solve the specific wear problems of your applications.

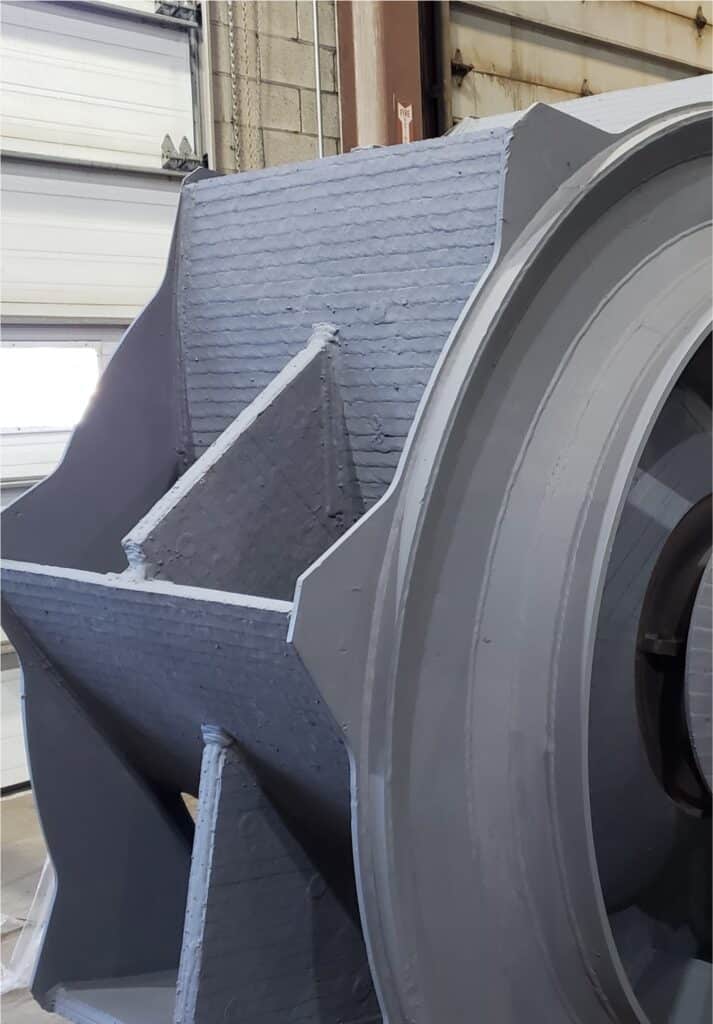

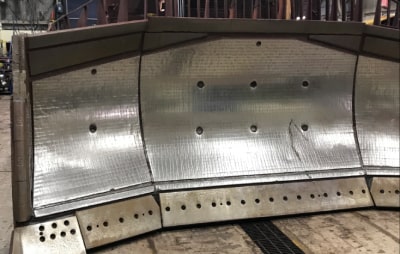

We then combine our ability to quickly manufacture different types of carbide overlays with our cutting, forming, and assembly expertise to design a unique solution to your needs for wear plates, pipes or complex assemblies.

Each finished product is therefore unique in shape, carbide deposit type and thickness, base metal thickness and mounting system and is ready for installation.

We manufacture :

We are proud to help optimize your operations with unique, innovative products, manufactured in our Canadian plant with very reasonable lead times.

Bring us your challenge !

Due to their unique metallurgical properties and great hardness, carbide overlays (CCOs) propose an excellent abrasive wear resistance and offer better wear performances than hardened steel.

They are available in several types of carbide deposits, each with different chemical compositions to cover a wide range of applications at different abrasion levels, impact levels and operating temperature ranges:

These material options can be used as a deposit of various thicknesses ranging from 1/16″ to 1/2″, applied to a mild steel, hardened/tempered steel or stainless steel substrate.

The steel backing provides impact resistance and the carbide deposit provides abrasion resistance to form a thin, lightweight, versatile lining.

The Steelguard product line therefore offers customized solutions to your unique abrasive wear problems.

Steelguard Chrome is a high density, high performance chrome carbide lining for general purpose applications.

Ideal for surfaces requiring high abrasion resistance, it consists of a mild steel, tempered steel or stainless steel substrate onto which Steelguard Chrome is deposited.

The Steelguard Chrome deposit, with a typical hardness of 57-60 HrC, consists of an austenitic matrix microstructure filled with chromium carbides.

Steelguard Super Slide offers a polished non-stick surface to address material adhesion or clogging issues while providing excellent wear resistance.

The low coefficient of friction of the wear surface thus reduces sticking and makes the product ideal for use in chutes, hoppers, buckets and truck bodies.

Manufactured from Steelguard Chrome, the surface of the carbide deposit is subsequently ground to a very smooth, low friction finish.

Steelguard Complex is designed for very heavy-duty applications where loads and abrasion levels are extreme.

The carbide deposit consists of several types of fine carbides in very high concentration and offers greater hardness than a standard chrome carbide overlay, thus providing superior performance.

The austenitic matrix consists of fine carbides of chrome, niobium, vanadium and tungsten in high concentration with a hardness of 63-67 Hrc.

Steelguard Complex is also abrasion resistant up to 1500°F and is ideal for tackling fine particle abrasion.

Steelguard Titanium is a unique overlay ideal for wear protection of surfaces exposed to high impact rates.

Consisting of a matrix of finely dispersed chrome and titanium carbides, the overlay deposit can be combined with a thick mild or tempered steel plate.

With a hardness of 56-60 Hrc, Steelguard Titanium will remain wear resistant up to 1200°F.

Steelguard Titanium is ideal for applications exposed to very large particles hitting surfaces at high speeds, creating lots of impacts.

Steelguard Tungsten is designed to solve wear challenges on applications of extreme abrasion by fine particles without impact.

This overlay consists of a matrix of chrome, niobium, vanadium and tungsten carbides, which is deposited on a mild steel or stainless steel substrate.

Steelguard Tungsten can be produced in thicknesses as thin as 1/8″ and 1/4″.

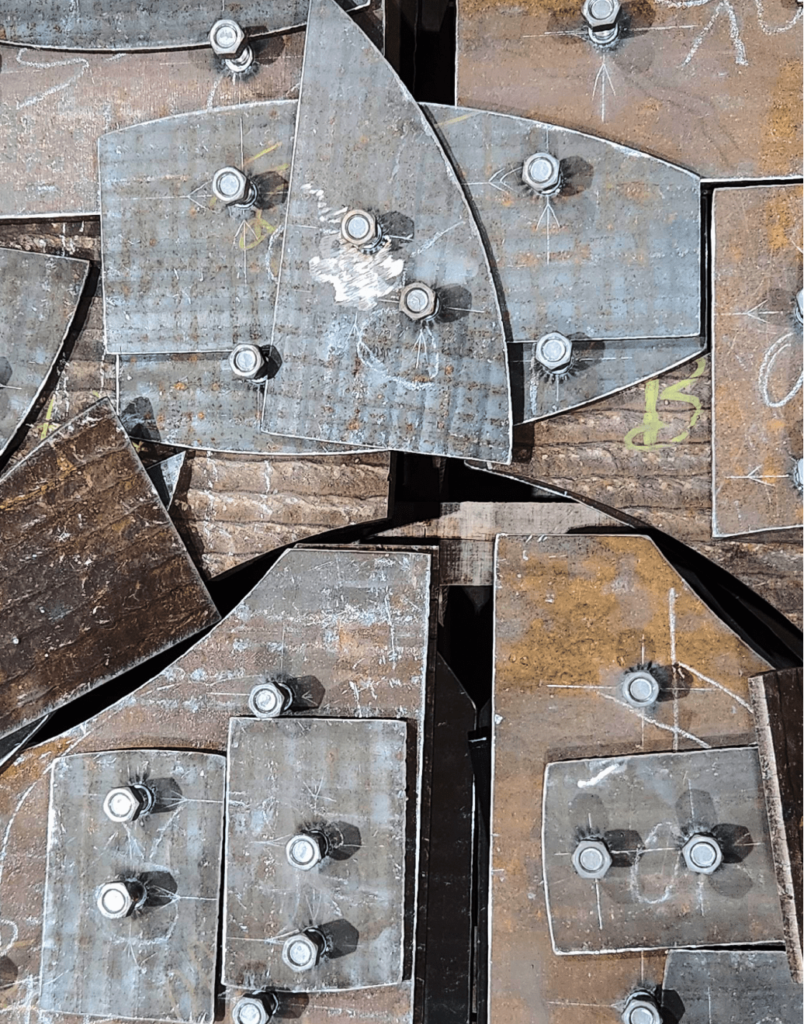

1 – Threaded studs welded on the back, any length and thread

2 – Welded conical inserts to receive conical headed bolts

Steelguard is the partner of several

industrial sectors.

1/16″ to ½″ in 1/16″ increments